Photothermal Tomography for Locating and Quantifying Defects in Composites: Empowering Advanced NDT with CICNDT and voidsy gmbh

Composite Inspection and Consulting LLC (CICNDT) remains at the forefront of delivering cutting-edge non-destructive testing (NDT) solutions, with a particular focus on Photothermal Tomography, across industries such as aerospace, wind energy, and automotive.Their mission to ensure the integrity and longevity of advanced materials through innovative inspection methods, precise execution, and a commitment to safety and quality aligns seamlessly with the breakthrough technology of the voidsy gmbh’s 3D V-ROX photothermal tomography system. This partnership strengthens CICNDT’s continued efforts to revolutionize NDT services, helping them meet the increasingly complex needs of industries reliant on modern composite materials like carbon fiber-reinforced polymers (CFRP).

Tackling the Complexities of Composite Materials

CFRP materials are widely used in sectors such as aerospace and wind energy due to their excellent strength-to-weight ratio. However, their heterogeneous and anisotropic nature presents unique challenges in detecting defects, such as disbonds, delaminations, and foreign object debris (FOD). Traditional ultrasonic inspection methods, while effective, often require contact with the material and are time-intensive, making them less than ideal for large-scale or mobile inspections. CICNDT’s commitment to improving inspection methodologies has led them to embrace advanced NDT techniques, including laser shearography, ultrasonic phased array, and thermal testing. The addition of voidsy gmbh’s 3D V-ROX photothermal tomography system represents a leap forward in non-contact, high-precision defect detection for composite structures.

The 3D V-ROX System: Redefining Composite Inspection

Developed by voidsy gmbh, the 3D V-ROX photothermal tomography system offers a significant upgrade over standard thermography methods by enabling 3D visualization of defects. Traditional infrared techniques only provide surface-level data, limiting the ability to fully assess defect size or depth. However, the 3D V-ROX system leverages transient heat diffusion to reveal the precise size, depth, and distribution of internal defects within composite materials. This advanced system aligns perfectly with CICNDT’s dedication to employing cutting-edge technology for superior defect detection, especially in aerospace components such as wings and fuselage, where safety and integrity are paramount.

This image showcases voidsy’s 3D V-ROX Photothermal Tomography device, a cutting-edge tool used for non-destructive testing (NDT) of composite materials. This portable system provides high-precision defect detection, making it ideal for industries such as aerospace and wind energy. Image courtesy of voidsy.

By utilizing 3D V-ROX, CICNDT can detect defects that traditional methods might miss, thereby preventing costly failures and enhancing the structural integrity of critical components. This system’s non-contact nature makes it particularly valuable in environments where traditional ultrasonic testing would be impractical, and its ability to generate detailed 3D representations of defects ensures comprehensive inspections.

Enhancing Efficiency and Safety in Aerospace and Wind Energy

In the aerospace industry, the ability to maintain the structural integrity of components such as CFRP aircraft spoilers is critical. The 3D V-ROX system excels in inspecting these complex structures, revealing defects like FOD, disbonds, and delaminations that can compromise performance. For CICNDT, this system offers an invaluable tool for reducing maintenance downtime while enhancing safety and reliability. The precise data provided by 3D V-ROX allows for a more efficient assessment of aircraft components, ensuring that maintenance is proactive rather than reactive.

Similarly, in the wind energy sector, where large composite structures like turbine blades are subjected to harsh environmental conditions, the 3D V-ROX system provides robust solutions for detecting defects that could impair performance. CICNDT’s advanced bond testing and phased array ultrasound techniques have already set the standard for inspecting wind turbine blades, and voidsy’s technology adds a new level of precision and depth to their inspection processes.

3D Photothermal Tomography in Action

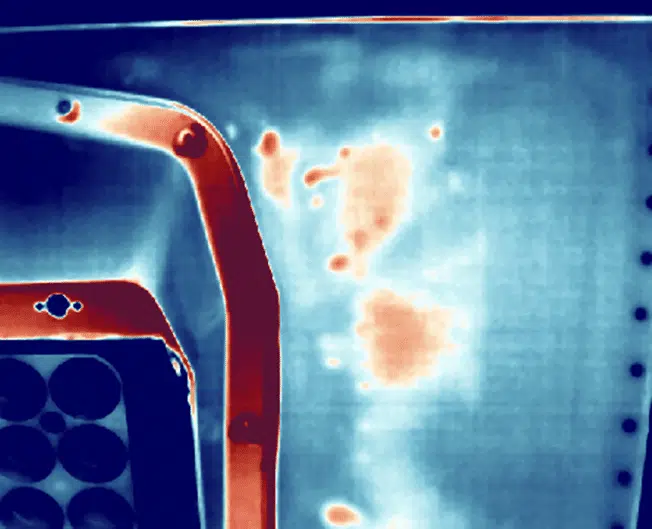

One of the critical advantages of the 3D V-ROX system is its ability to provide real-time 3D reconstructions of defects within composite materials. For example, when inspecting a CFRP aircraft spoiler with a sandwich construction, the system was able to detect FOD at various depths within the composite layers. This capability enables inspectors to assess not just the presence of defects but also their precise location and size, leading to more informed decision-making regarding repairs or part replacements. The integration of 3D imaging allows CICNDT to visualize the defects in multiple cross-sections, helping engineers ensure the component meets safety and performance standards.

This image showcases voidsy’s 3D V-ROX Photothermal Tomography device in action, inspecting the composite material of a helicopter tail boom. The cutting-edge technology offers high-precision, non-destructive testing (NDT) for detecting internal defects, ensuring the structural integrity of aerospace components. Image courtesy of voidsy.

In another case, the system was used to inspect wind turbine blades, detecting subsurface defects that traditional NDT methods might overlook. The ability to generate A-scans, B-scans, and C-scans from the thermal data ensures a complete picture of the component’s health, without the need for secondary inspection methods.

Conclusion: Leading the Future of Non-Destructive Testing

CICNDT’s integration of voidsy gmbH’s 3D V-ROX photothermal tomography system marks a new chapter in the evolution of non-destructive testing. By combining state-of-the-art technology with their extensive industry expertise, CICNDT continues to lead the NDT field, ensuring the structural integrity of critical components in aerospace, wind energy, and beyond. This partnership exemplifies their shared vision of advancing NDT through innovative, precise, and efficient solutions that enhance both safety and operational effectiveness. As industries continue to evolve, CICNDT and voidsy remain committed to pushing the boundaries of what is possible in the realm of composite inspections.

References

- CICNDT – Mission, Vision, and Values. Retrieved from cicndt.com

- Photothermal Tomography in Composite Inspection – voidsy gmbh, 2024.

- 3D V-ROX Photothermal Tomography System: Enhancing NDT Efficiency – Aerospace Applications, 2024.

- Innovations in NDT for Wind Energy – CICNDT and voidsy Partnership, 2024.