The voidsy 3D V-ROX is a pioneering, compact, and intelligent photothermal tomography system that enables precise 3D imaging of concealed material and structural defects.

Photothermal Tomography

As a cutting-edge technology in the field of Non-destructive Testing (NDT), it provides an advanced solution for industries requiring high-resolution, non-contact inspections. CICNDT is proud to integrate this innovative system into our suite of NDT services, offering enhanced detection capabilities for critical applications.

Photothermal (PTT) Tomography – Overview

NDT and Evaluation with PTT

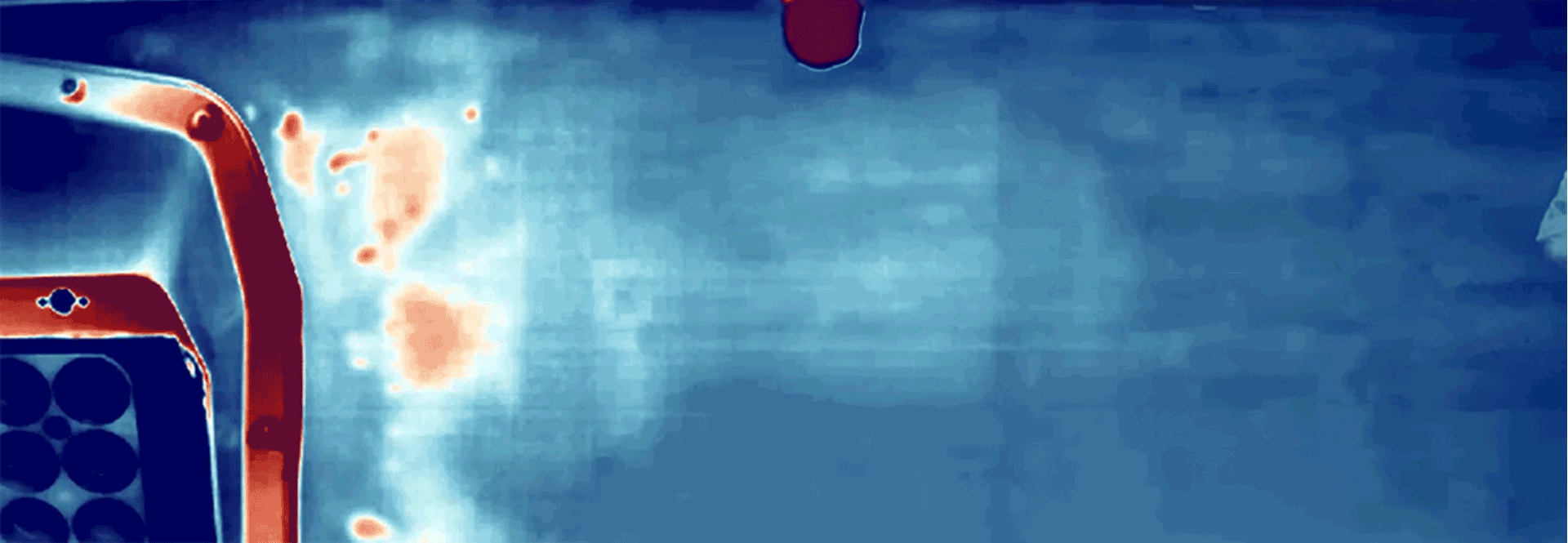

Composite Inspection and Consulting employs state-of-the-art active photothermal thermography technology developed by voidsy gmbh to provide highly accurate non-destructive testing services. This technique uses an optical energy source to induce thermal changes in components, with an infrared camera capturing surface temperature data during and after excitation. The resulting thermal response is analyzed to extract quantitative information about material structure, properties, and defects.

In addition to utilizing this technology, CICNDT also offers voidsy gmbh systems for sale to clients seeking advanced in-house testing capabilities.

Features:

- Compact, Smart, and Easy to Automate: Streamlined for efficient integration.

- No Water or Coupling Gel Needed: Simplifies setup and operation.

- Quantitative Defect Sizing: Delivers accurate assessments.

- High-Speed Inspection: Ensures rapid and reliable results.

- Flexible Configurations: Supports both pulse-echo and through-transmission methods.

Advanced NDT and Evaluation with Photothermal Tomography

CICNDT, in collaboration with voidsy gmbh and Omni NDE, offers advanced Non-destructive Testing (NDT) services using Photothermal Tomography. The voidsy 3D V-ROX system, combined with Omni NDE’s expertise in automation and sensor technology, enables precise, contactless inspections of complex materials and assemblies.

PTT works by applying optical energy to induce thermal changes in components, with an infrared camera capturing surface temperature data during and after excitation. This thermal response is analyzed to extract detailed information about the material’s structure, properties, and potential defects. Omni NDE ensures that this system not only detects defects but also provides imaging and measurement capabilities previously unavailable in industrial NDT.

We proudly implement this technology and offer the voidsy 3D V-ROX system to clients seeking to enhance their in-house testing capabilities.

Key Features:

- Seamless Integration: Developed with Omni NDE’s automation expertise.

- Non-Contact Operation: Simplifies setup with no need for water or coupling gel.

- Accurate Defect Sizing: Delivers precise assessments.

- Rapid Inspections: Optimizes both time and cost.

- Versatile Configurations: Supports multiple testing methods.

A Global Collaboration in Advanced NDT with Photothermal Tomography

CICNDT, in a global collaboration with voidsy gmbh and Omni NDE, enhances non-destructive testing (NDT) capabilities by merging voidsy’s 3D V-ROX photothermal tomography system with Omni NDE’s automation expertise and CICNDT’s extensive field knowledge. This powerful combination sets a new standard in NDT.

The 3D V-ROX system employs an innovative approach where controlled thermal energy is applied to materials, and advanced infrared imaging captures the resulting thermal behavior. This method enables precise detection of subsurface defects, providing critical insights for industries that depend on the integrity of complex materials.

This collaboration goes beyond mere technological integration—it merges specialized expertise to enable CICNDT to offer high-precision testing services with increased reliability. Clients benefit from CICNDT’s field-proven application of this technology and have the option to purchase the 3D V-ROX system for their in-house quality assurance programs.

Key Benefits of Global Collaboration:

- Comprehensive Expertise: Integrates voidsy’s innovative design with Omni NDE’s automation prowess and CICNDT’s solid experience in field applications, especially in austere environments.

- Rugged and Reliable Equipment: The 3D V-ROX system is engineered to be robust, portable, and practical—ideal for use in challenging conditions where CICNDT technicians need consistent, dependable performance.

- Precision and Speed: Provides quantitative defect analysis and high-speed inspections, ensuring accuracy and efficiency in even the most demanding environments.

- Adaptable Automation: Developed with Omni NDE’s automation expertise, offering practical and reliable automation that guarantees unwavering results, whether in controlled settings or the harshest field conditions.

Through this global collaboration, CICNDT delivers state-of-the-art NDT solutions, ensuring the safety and reliability of critical components across various industries, while also empowering clients with cutting-edge technology for their own operations.